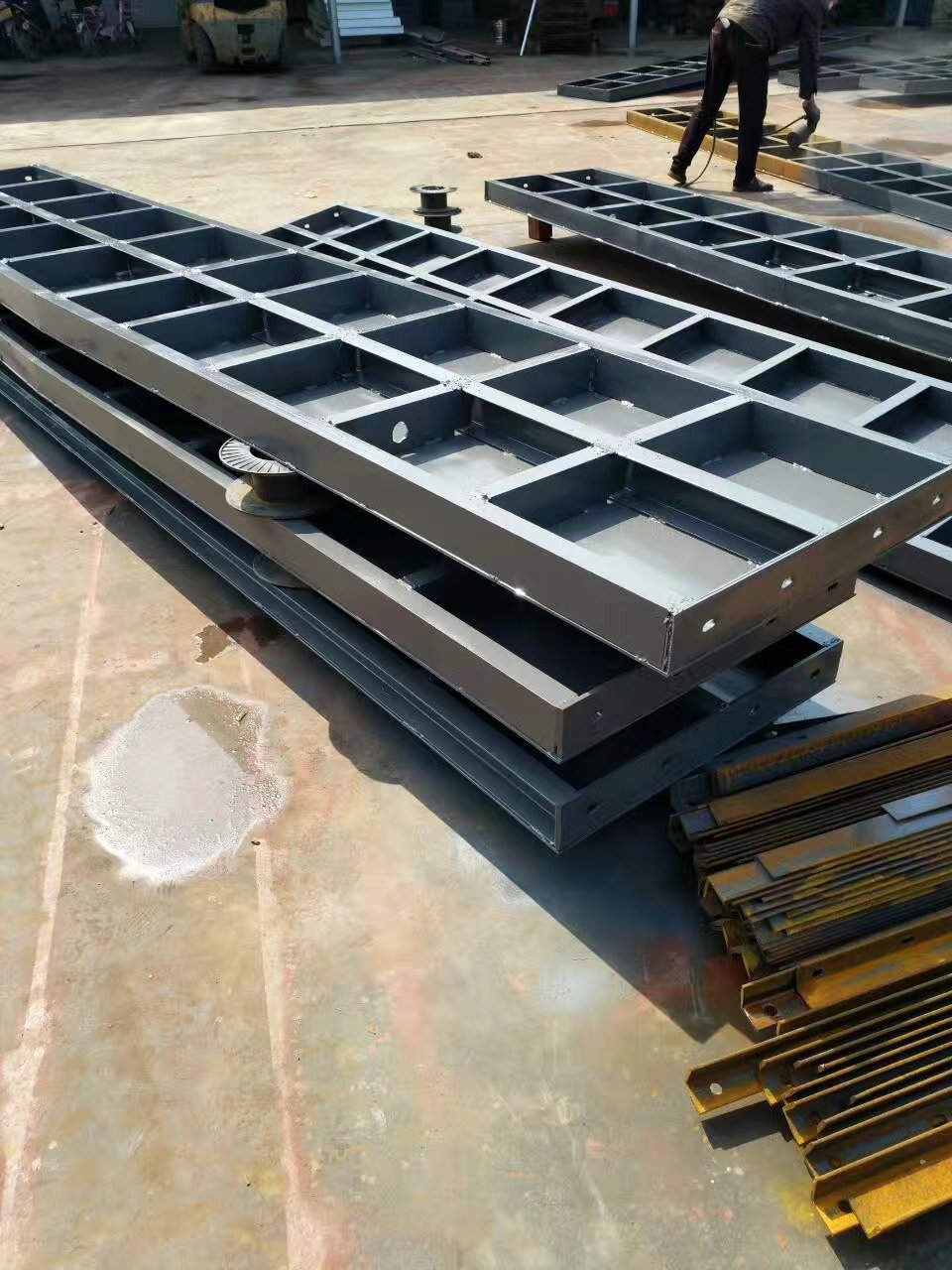

高速防撞护栏模具

高速防撞护栏模具的生产方式是现浇的,他在生产使用的时候有几点需要特别注意:一,了解模具的工作原理及使用方法,正确操作,如果有不懂的要及时和厂家的技术顾问了解并且解决。二,检查模具是否有磨损变形有杂质,如果变形或者没有清理干净就进行使用的话,高速防撞护栏模具生产出的产品并不光滑平整;三,将模具放置于一个平整的地方,减少震动和噪音对整体形状的影响;四,做好日常维护保养,使用完毕后清除残渣废料,不能暴晒受潮;五,在出现故障的时候及时送检,根据受损情况维修或者更换。六,高速防撞护栏模具的保存也十分重要,在存储模具的地方要应干燥通风,地面平整,干净整洁,有充分的采光或足够的照明,,其中的通道能够有足够的空间,便于调运模具,而且每次调用的时候应该有记录,什么时候出库,什么时候入库,使用情况,有无损坏等等都需要记录。七,在进行生产制作时一定要放在平地上,方式其变形倾斜,不能站立。有着十分突出的两片式结构,是上下贯通的,由于其拆卸开后是呈片状的,表面较为平整,重量相对较轻,体积也更小,所以也就十分便于搬运和拆卸,多是用于道路两侧护栏的现场浇筑生产。这种生产模式较之传统的预制生产有一个很大的优势村在,就是产出混凝土护栏是不需要经过长距离运输的,用户在使用高速防撞护栏模具可以选择直接在需要浇筑混凝土护栏的位置上拼装模具并进行固定,这样由于模具的底部没有钢板衬托,一旦浇筑混凝土泥浆就没有办法进行移动了,凝固后就会自然地与公路融为一体,抓地的力度也就更大,因此在抗撞击能力提高的同时也省去了复杂的安装步骤,使用现浇 的混凝土护栏的安全系数也就相对更高。与此同时,使用混凝土护栏模具进行生产更加节省工程时间,因为现浇过程生产得更快,往往在注浆后八小时就可以进行拆模,由于模具表面更加光滑,由涂抹了脱模剂配合生产,所以拆模十分简单快速,只要混凝土基本凝固就可以拆除而不会影响防撞护栏的形状。he production mode of high-speed anti-collision guardrail mold is cast-in-place. He needs to pay special attention to several points in production and use: first, understand the working principle and use method of the mold, and operate correctly. If you don't understand, you should timely understand and solve with the technical consultant of the manufacturer. 2、 Check whether the mold is worn, deformed and impurities. If it is deformed or not cleaned up, the products produced by the mold of high-speed anti-collision guardrail are not smooth and smooth; thirdly, place the mold in a flat place to reduce the impact of vibration and noise on the overall shape; fourthly, do a good job in daily maintenance, and remove the residue and waste after use, and do not expose Five, in the event of failure, timely inspection, repair or replacement according to the damage. 6、 It is also very important to keep the mold of high-speed anti-collision guardrail. The place where the mold is stored should be dry and ventilated, the ground should be flat, clean and tidy, and there should be sufficient lighting or lighting in the place where the mold is stored. There should be enough space in the channel to facilitate the transfer of the mold. Moreover, the time of each call should be recorded. When the mold is put out of the warehouse and when it is put into storage, the use condition should be undamaged Bad and so on need to be recorded. 7、 In the production process, it must be placed on the flat ground in such a way that the deformation is inclined and cannot stand. It has a very prominent two-piece structure, which is connected from top to bottom. Since it is in flake shape after being disassembled, its surface is relatively flat, its weight is relatively light and its volume is smaller. Therefore, it is very convenient for handling and dismantling. It is mostly used for on-site pouring production of guardrails on both sides of the road. Compared with the traditional prefabrication production, this production mode has a great advantage, that is, the production of concrete guardrail does not need to go through long-distance transportation. Users can choose to directly assemble and fix the mold at the position where the concrete guardrail needs to be poured when using the high-speed anti-collision guardrail mold. In this way, since there is no steel plate at the bottom of the mold, once the concrete slurry is poured There is no way to move. After solidification, it will naturally integrate with the highway, and the strength of grasping the ground will be greater. Therefore, while improving the anti-collision ability, it also saves the complicated installation steps, and the safety factor of cast-in-place concrete guardrail is relatively higher. At the same time, the use of concrete guardrail mold for production is more time-saving, because the cast-in-place process production is faster, often in the eight hours after grouting can be removed, because the mold surface is more smooth, by coating the release agent with production, so the mold removal is very simple and fast, as long as the concrete is basically solidified, it can be removed without affecting the shape of the anti-collision guardrail 。